The dredge pipeline is an indispensable part of the dredging project. The silt excavated from the bed surface and raised to the water surface needs to be transported to the destination for further treatment or treatment. Its horizontal transportation methods include trailing suction dredger transportation, mud barge Transportation, and dredging pipeline transportation. Generally speaking, mechanical dredging uses mud barge transportation, cutter suction dredger uses pipeline transportation, and trailing suction dredger can be directly transported by ship. Compared with other stages, the horizontal transportation of dredged sediment has a relatively small impact on the environment, and its main risk comes from the leakage of dredged sediment. Dredge pipelines are the most cost-effective choice for horizontal transportation

Commonly Used Dredging Pipelines

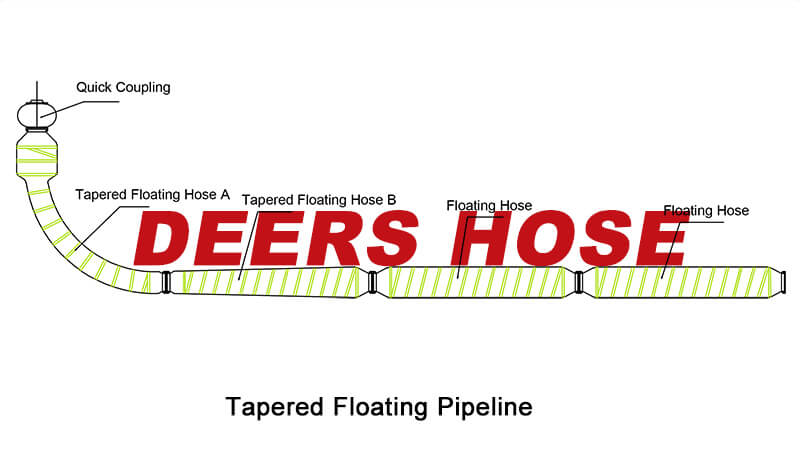

Type 1.(Without Hose A&B)Normal Floating hose pipeline

Type 2.(With Hose A&B)Tapered floating hose includes Hose A and Hose B. Hose A is that one end has buoyancy and the other has no buoyancy. The buoyancy end is connected to quick coupling. And the non-buoyancy end is connected to hose B. Hose B is directly connected to normal floating hoses. Hose A can replace the dredge ball joint. Tapered floating hose and normal floating hoses can form a tapered floating pipeline.

2.Steel pipe+ Discharge hose + PE float

Steel pipe with good wear resistance and easy to install Discharge hose’s inner cover with excellent abrasion resistance and high quality. PE float with good flexibility and excellent impact resistance, particularly suitable for construction in the open sea.

3.HDPE pipe + Discharge hose + PE float

HDPE pipe with the feature of resistance against galvanic corrosion, Resistance against decay.

The different of dredge pipelines

1.quality

Normal floating hoses pipeline

the first rubber discharge hose connects with dredging quick-release coupling. It is usually equipped with a steel ring floater to floating above water level for easy installation.

HDPE pipe + discharge hose + PE float:

HDPE with good efficiency, reliable channel interface, aging resistance, and corrosion, etc.

Steel pipe+ discharge hose + PE float:

With good wear resistance, the steel pipe was used widely in transporting.

2.application

HDPE pipe + discharge hose + PE float:

This type Suitable for small wind and waves, offshore, river, lake operations.

Steel pipe+ discharge hose + PE float:

Under the action of the pipeline and wind and waves, the Steel pipe can increase the flexibility of the entire pipeline.

Normal floating hoses pipeline

This type of hose is suitable for dredging pipelines under impact from huge sea waves

In addition to these types of mainstream combined pipelines on the market, you can also choose the material of each pipeline. For example, discharge hose includes normal discharge hose, armored discharge hose, ceramic discharge hose. PE float includes rubber float and internal pe float. Of course, different dredge pipeline suit different application scenarios. You should choose the best product for you.