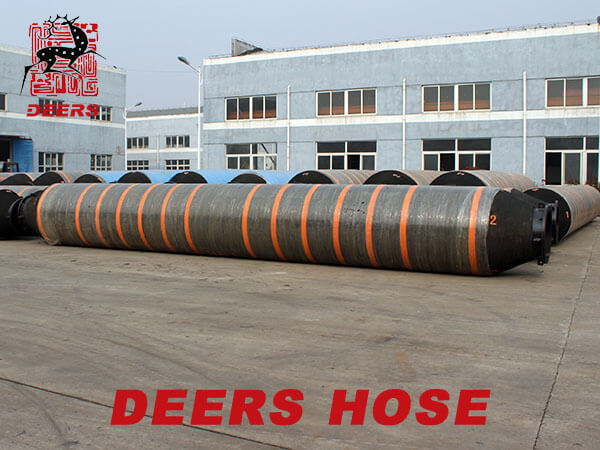

The dredge rubber hose features high strength and flexibility. A flexible dredging hose widely used in dredgers for silt/gravels conveyance. It is abrasion and wear-resistant to ensure long service life. The rubber hose has excellent salty, weather, and other chemical resistance performance to ensure good performance in corrosive environments. Dredging hose has a long history. We have different dredging hose to transport different dredging media.

Types of flexible dredge hose

The most obvious feature of the self-floating hose is that it floats on the surface of the water, has wind and wave resistance, corrosion resistance, high working pressure, long service life, and easy assembly.

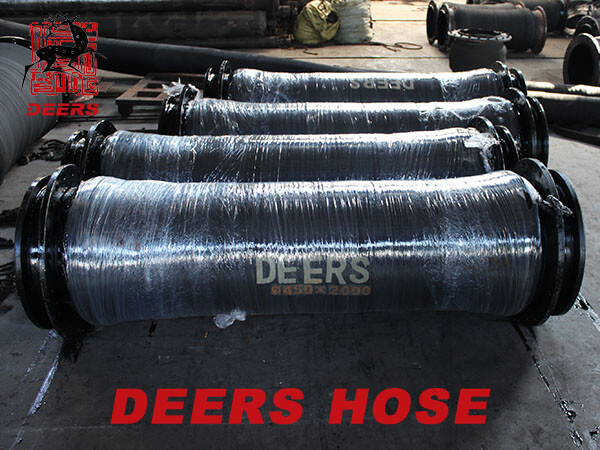

Dredge discharge hose refers to (cutter-suction) dredger and other dredging machinery to transport mud, In the combined pipeline, the main function of the discharge rubber hose is to connect the dredging steel pipe to make the pipeline more flexible to meet the construction requirements.

Different from the positive pressure working mode of the discharge hose, the suction hose is installed on the inlet of the pump, which is a negative pressure working mode

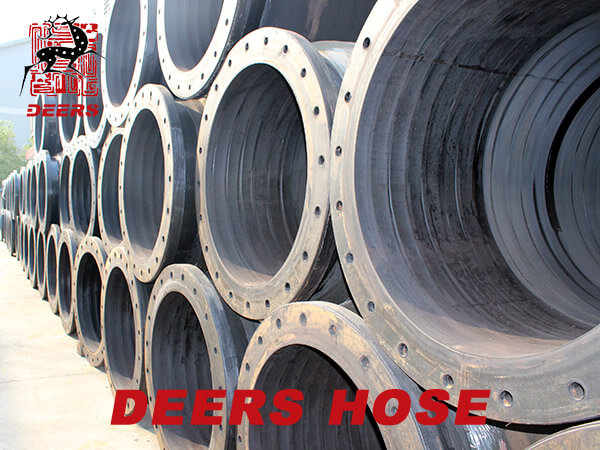

For relatively hard media such as coral reefs, in order to extend the service life of the pipeline, on the basis of the conventional dredging pipeline, it is improved into the armored hose and super wear-resistant ceramic hose. Also, we provide customized sizes and different materials of dredge hoses.

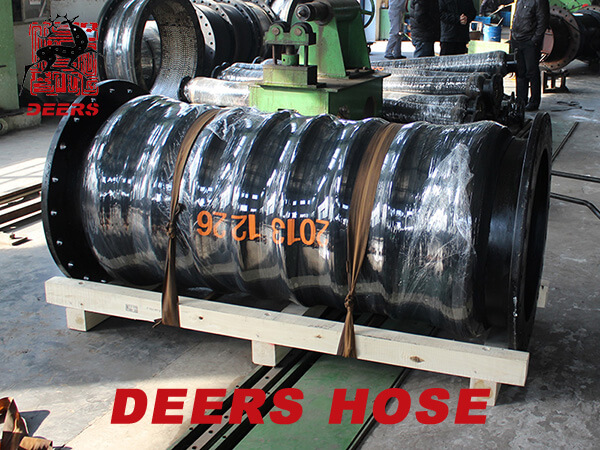

Armored Rubber Hose

Compared with ordinary dredging hose, the biggest difference of armored hose is that wear-resistant steel rings are added inside to improve the wear resistance of the pipelines and extend the service life. At present, we have armored discharge hose and armored self-floating hose.

Ceramic Rubber Hose

Similar to the armored hose, the ceramic hose is a new attempt by us. They are more wear-resistant than the armored hose, and can be used not only for dredging but also in the mining industry.