- Raw rubber, and compounding agents

The raw rubber materials which are used for dredging rubber hoses are generally based on NR, with synthetic rubber materials which have better wear resistance such as BR and SBR.

In compounding agents, materials with good reinforcing performance, large surface area, and small particle size, are used more in the inner rubber layer compound. It can improve the wear resistance, such as N220 series carbon black with small particle size instead of N330 series Carbon black is used in the rubber compound of the inner rubber layer. Some new dispersants, accelerators, tackifying resins, and antioxidants have been used in the manufacture of dredging rubber hoses. They can improve mechanical properties, and the physical, and environmental performance of the rubber.

- Metallic materials

The metallic materials used in the dredging rubber hose include binding steel wires for fixing the cord, flanges and connectors, steel rings in the reinforcement layer of the suction rubber hose, and wear-resistant rings in the armored dredging rubber hoses, etc.

- Improvement of reinforcing layer cord materials

In the 1980s, the reinforcement layer materials of dredging rubber hoses were mostly steel cords. Since the fatigue performance of steel wire is not good, and it is not resistant to seawater corrosion, which affects the working life of dredging rubber hoses, the steel cord is gradually withdrawn in the 1990s and replaced by nylon cord. Nylon cord has high strength and good affinity with the rubber. But nylon cord’s elongation is high (generally 23%), and when in the working state, the deformation of the dredging rubber hoses is large, which will accelerate the wear of the inner rubber layer. Now, large-diameter polyester industrial filaments are mostly used as cord fabrics for dredging rubber hoses. The polyester cord has good elasticity, low elongation (usually 15%), and the deformation of the dredging rubber hose under pressure is small. For cords with a wire diameter of 1.4mm, the braking force of a single strand can reach more than 90kg. In recent years, the research of new materials for cord fabrics has been having certain achievements.

- The other materials

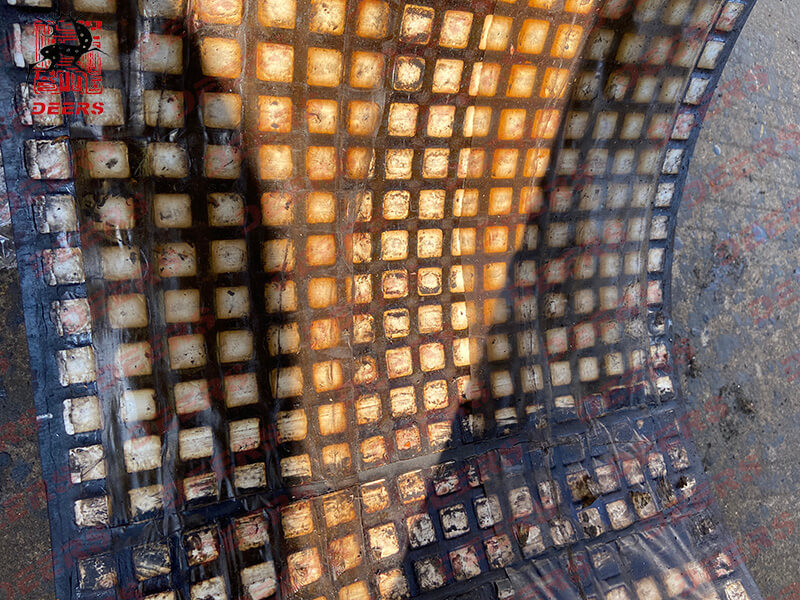

In recent years, other materials have been used in the manufacture of dredging rubber hoses. Such as ceramic materials. Ceramic material is an emerging composite material, the main component is Al2O3, which can be sintered at temperature above 1700 °C. using of this material for dredging rubber hoses can improve significantly the wear resistance of the hoses, reduce work resistance and work energy consumption.

Related Products